Water treatment has advanced rapidly in the last 30 years, making possible new levels of public health protection and water reuse. Today's advanced water treatment technologies go far beyond traditional filtration and disinfection. They harness the power of membranes, ultraviolet light, oxidation, and even artificial intelligence to produce safe, high-quality water—even from challenging sources.

Membrane Filtration: MF, UF, and RO

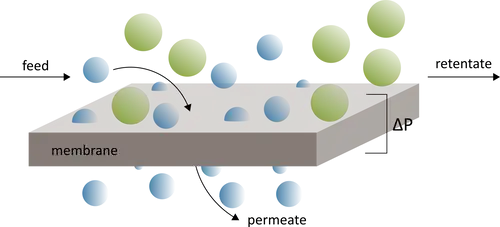

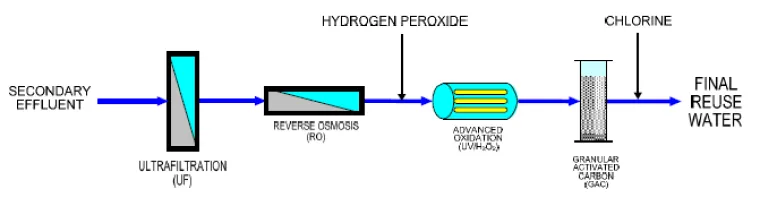

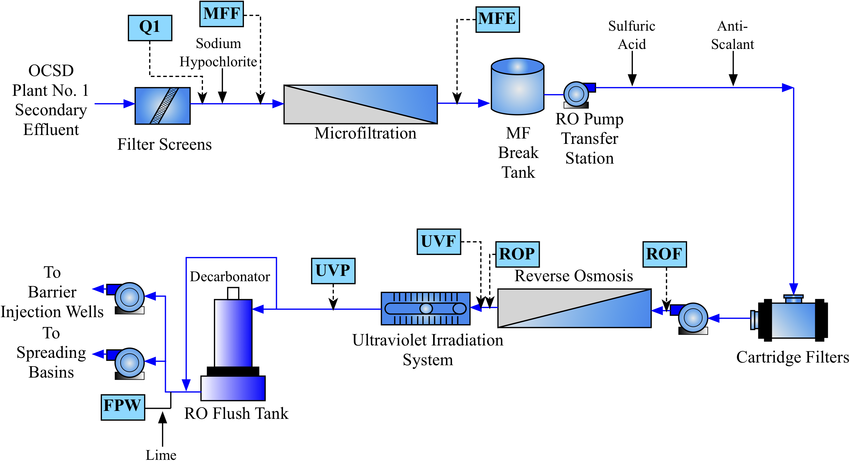

Membrane technologies are a cornerstone of modern water treatment. Microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO) each use semi-permeable membranes to separate contaminants from water, but they differ in pore size and what they remove:

- MF/UF: Remove suspended solids, bacteria, and some viruses. Often used as a pretreatment step.

- NF: Removes divalent ions (e.g., calcium, magnesium), hardness, and some organics.

- RO: Removes virtually all dissolved salts, small organics, and many contaminants of emerging concern (CECs). Central to potable reuse and desalination projects.

Advanced Oxidation Processes (AOPs)

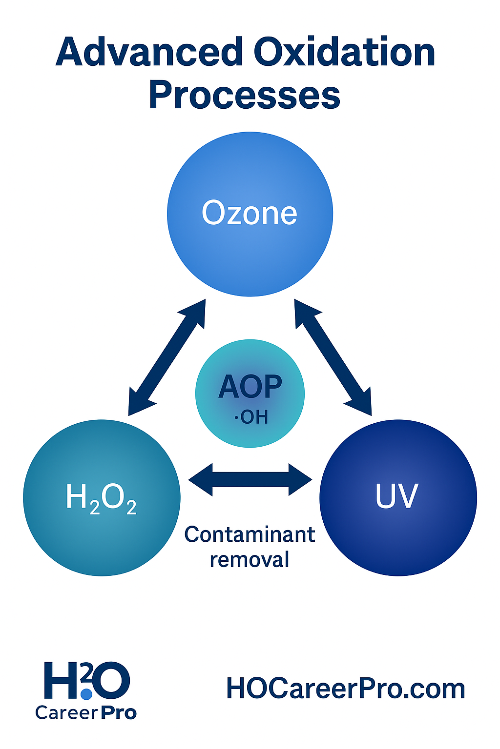

Advanced oxidation processes (AOPs) use combinations of oxidants (e.g., ozone, hydrogen peroxide) and UV light to generate hydroxyl radicals, which are extremely effective at breaking down organic contaminants, including many pharmaceuticals and micropollutants. These processes are essential in potable water reuse, removing contaminants that are resistant to conventional treatment.

Ultraviolet (UV) Disinfection

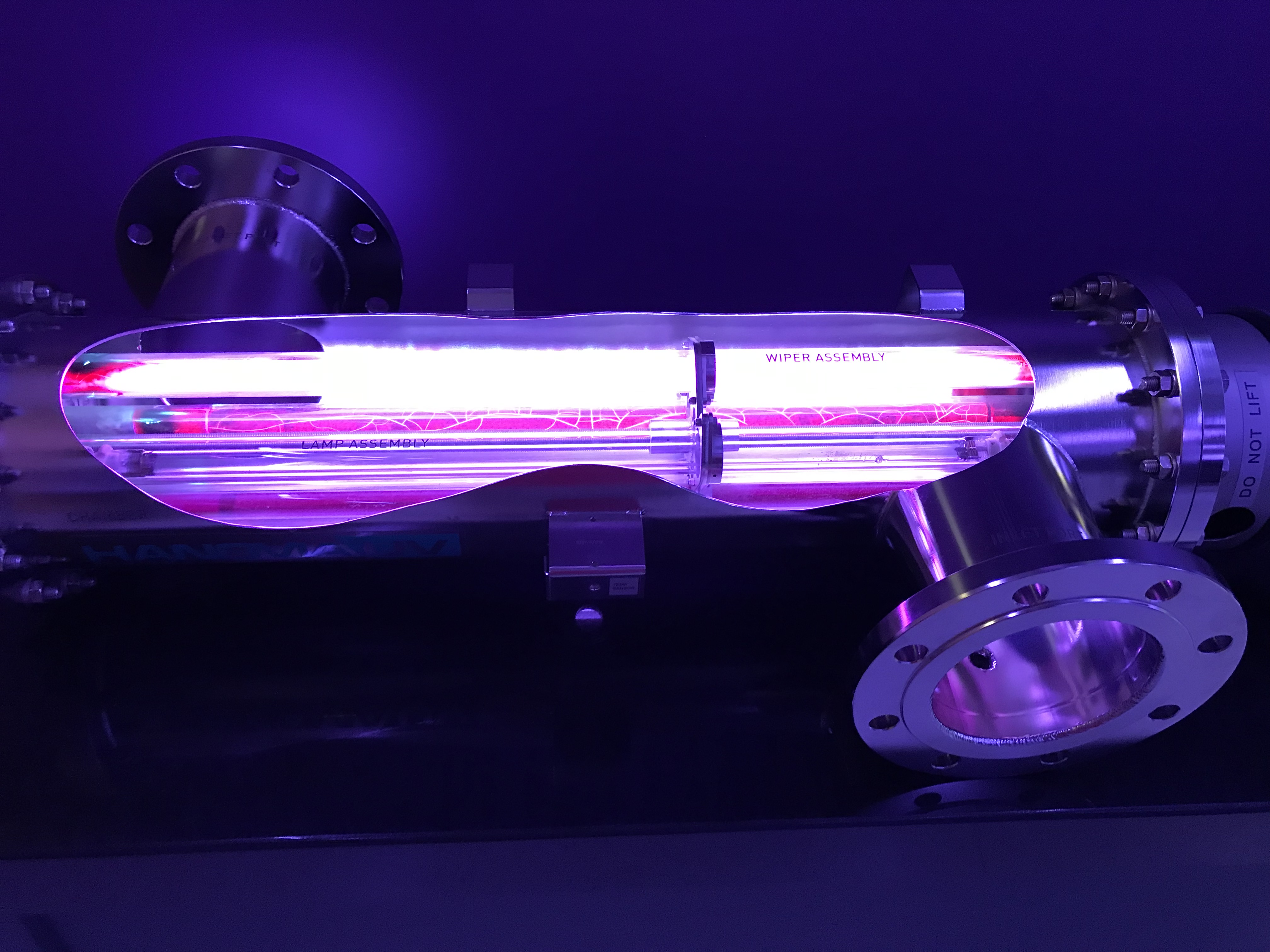

Ultraviolet (UV) disinfection is a physical process that inactivates bacteria, viruses, and protozoa by damaging their DNA. It is increasingly used as a final disinfection barrier, especially in potable reuse systems. UV combined with AOP (UV/AOP) provides both pathogen inactivation and chemical contaminant removal.

Ozone Treatment

Ozone is a powerful oxidant used to break down taste and odor compounds, inactivate microorganisms, and enhance the biodegradability of organics prior to biological filtration. Ozone is also a key component of many AOP systems.

Biological Activated Carbon (BAC) & Biofiltration

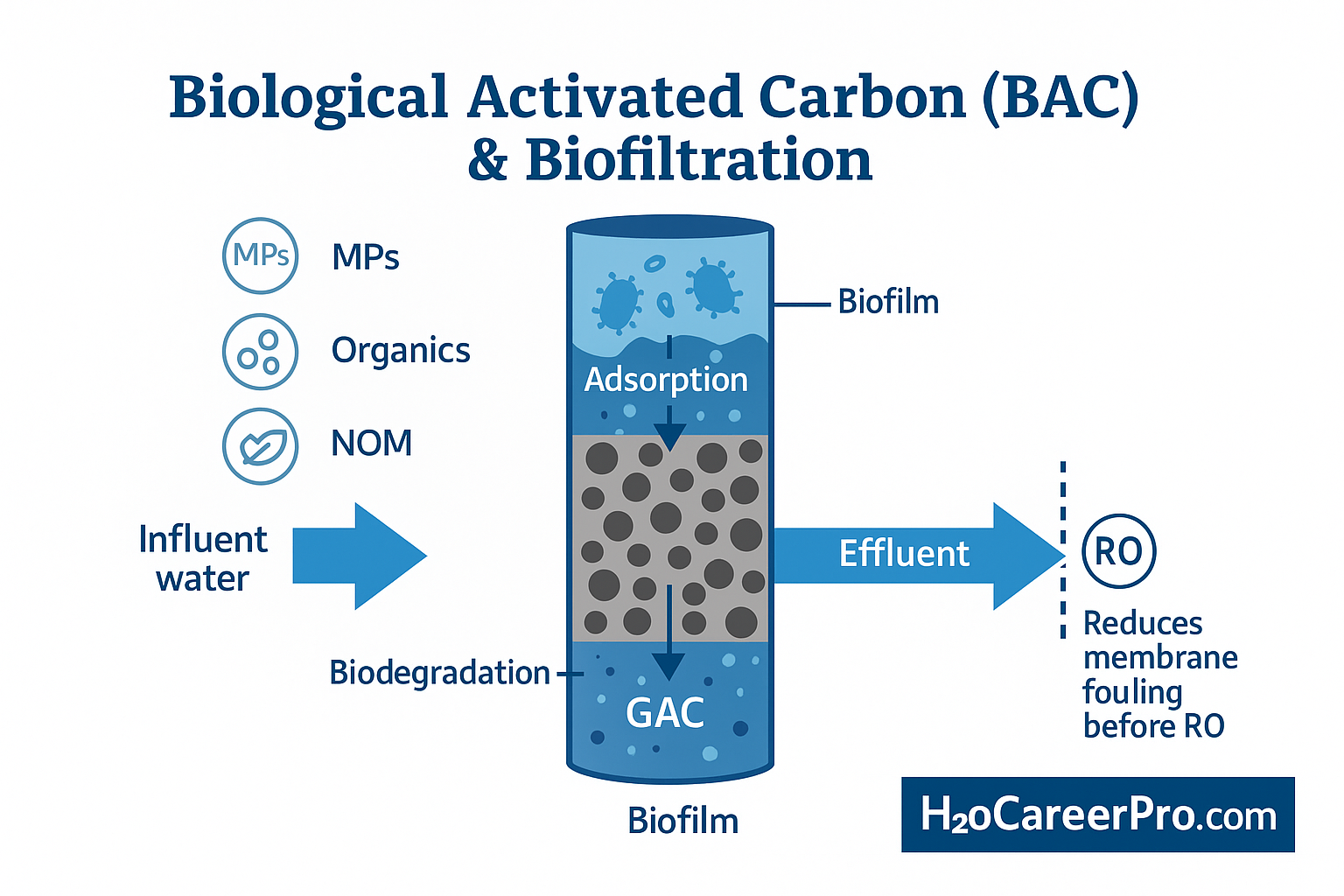

BAC and related biofiltration processes combine the adsorption capacity of granular activated carbon (GAC) with the biodegradation of organics by microorganisms. This approach is increasingly used as a pretreatment step before RO, reducing membrane fouling and removing contaminants that resist conventional filtration.

Potable Reuse: Closing the Water Cycle

Advanced water treatment enables potable reuse—treating wastewater to a standard where it can be safely returned to the drinking water supply. Potable reuse projects typically employ multiple barriers: MF/UF → RO → UV/AOP → BAC, plus extensive monitoring and automation. States like California, Texas, and Arizona are leading in this space.

Automation, Data, and A.I.

Modern plants use Supervisory Control and Data Acquisition (SCADA) systems, remote sensors, and, increasingly, artificial intelligence to optimize operations, predict maintenance, and ensure regulatory compliance.

- Predictive Maintenance: Sensors detect membrane fouling and schedule cleanings before failures occur.

- Regulatory Reporting: Automated monitoring ensures real-time compliance with strict state and federal standards.

Challenges and Opportunities

- Cost: Energy and maintenance requirements can be high for advanced processes like RO and AOP.

- Brine Management: RO produces concentrated waste streams that must be disposed of or further treated.

- Emerging Contaminants: New chemicals, PFAS, and microplastics require ongoing research and adaptation.

- Workforce Training: Operators must understand sophisticated controls, water chemistry, and integrated processes.

Case Study: Orange County Water District Groundwater Replenishment System (GWRS)

The GWRS in California is the world's largest potable reuse project, producing 130 million gallons per day of drinking water from treated wastewater using MF, RO, and UV/AOP. The project demonstrates the reliability and safety of advanced treatment for large-scale water supply.

Conclusion

Advanced water treatment technologies are critical for water security, environmental protection, and public health. As climate change and population growth stress traditional supplies, continued innovation in treatment, automation, and reuse will define the next era of water management.